Customer Service Representative

Immediate opening for a Customer Service Representative with experience handling both small and multinational accounts.

This customer service position is an exciting opportunity for those who would like to use their communication skills. On a daily basis you will receive incoming phone calls and e-mails, solve the appearing issues from foreign clients and businesses and find the best solutions

for the occurring problems.

We are looking for energetic applicants who can speak English fluently. The ideal candidate has experience in customer service representative positions but fresh graduates are also welcomed. This position is for someone who is willing to grow with our company and continue to

contribute for the long-term.

Job opening for US citizen or permanent residents only!

"Candidates must live in North NJ"

For consideration please forward your resume and salary requirements to:

John Wilson

BELL-MARK

331 Changebridge Road

Pinebrook, NJ 07058

Phone: 973-712-0413

careers@bell-mark.com

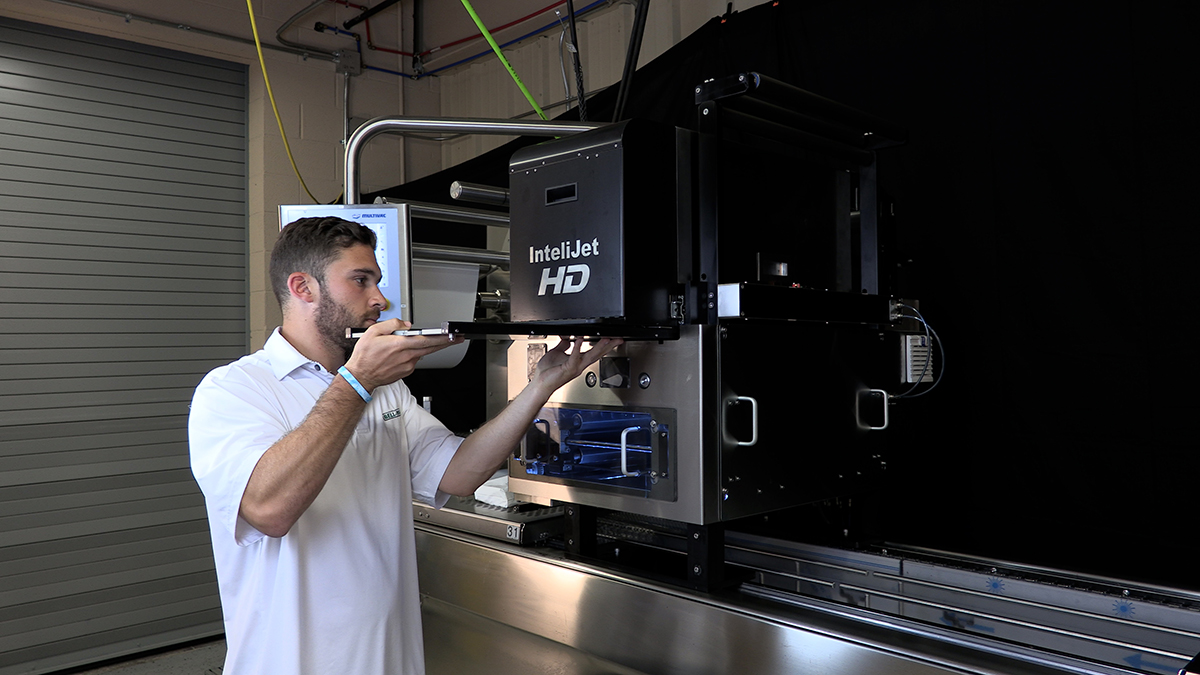

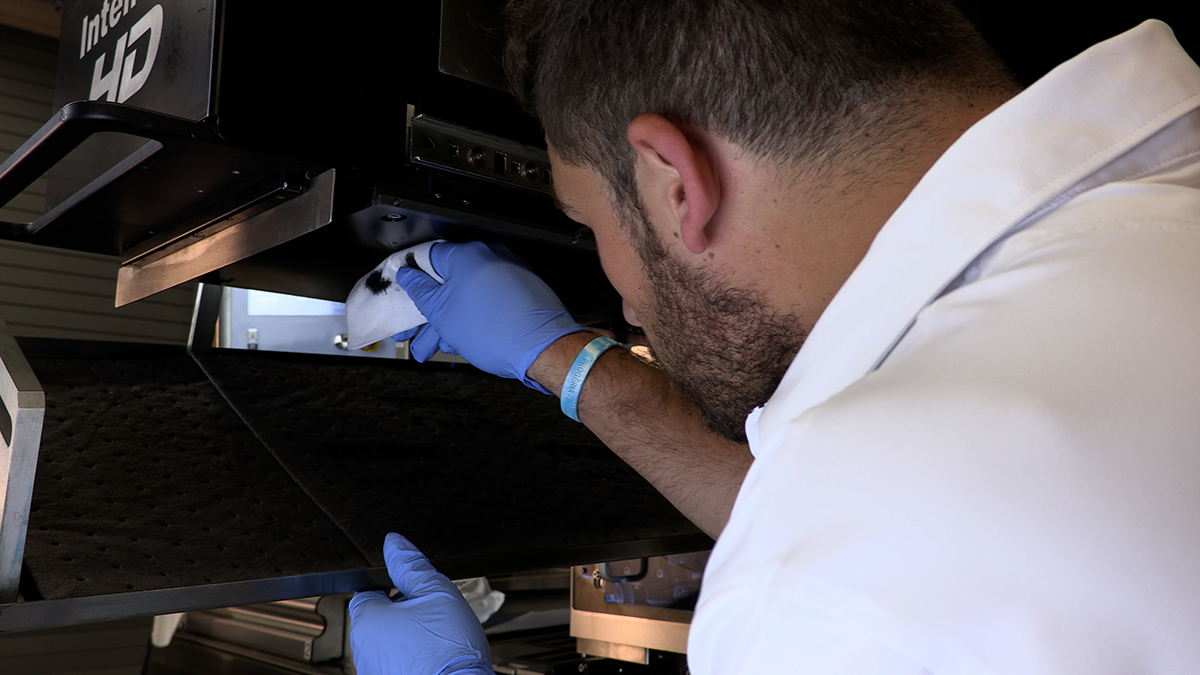

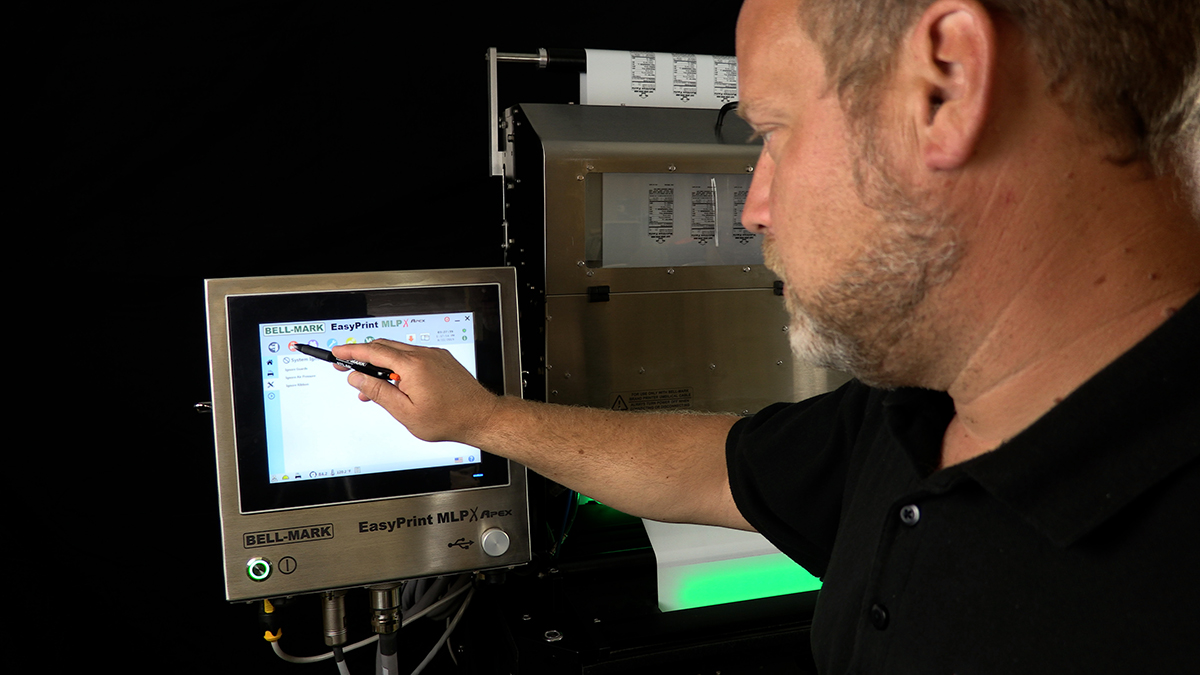

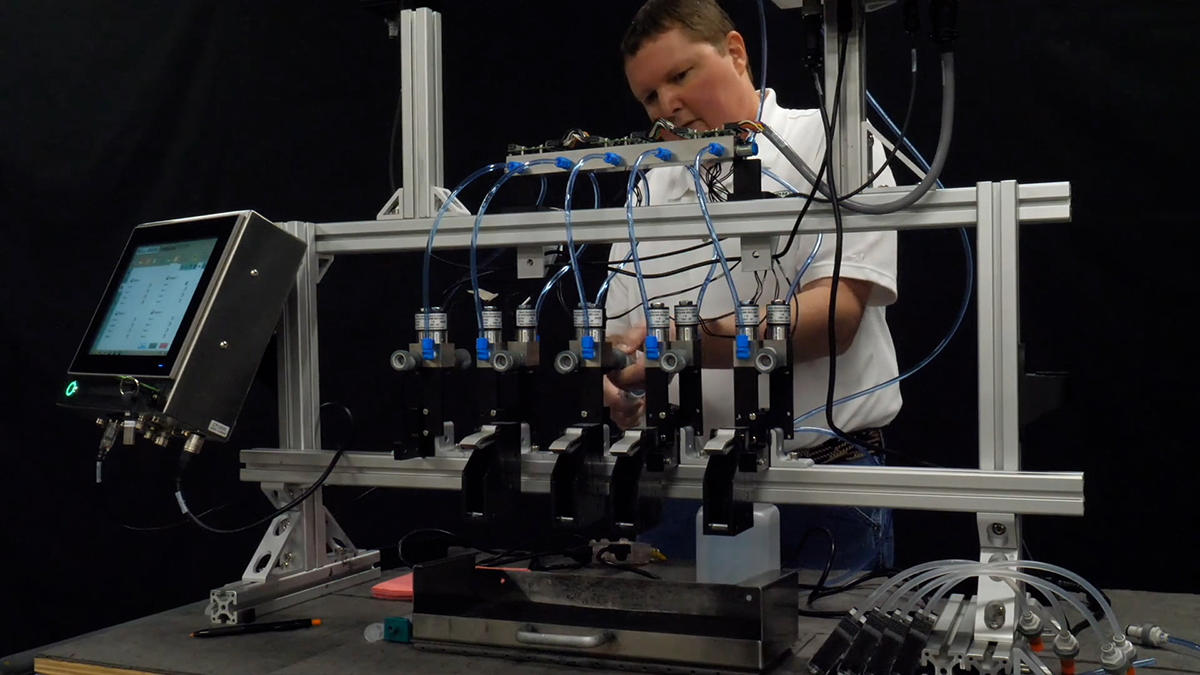

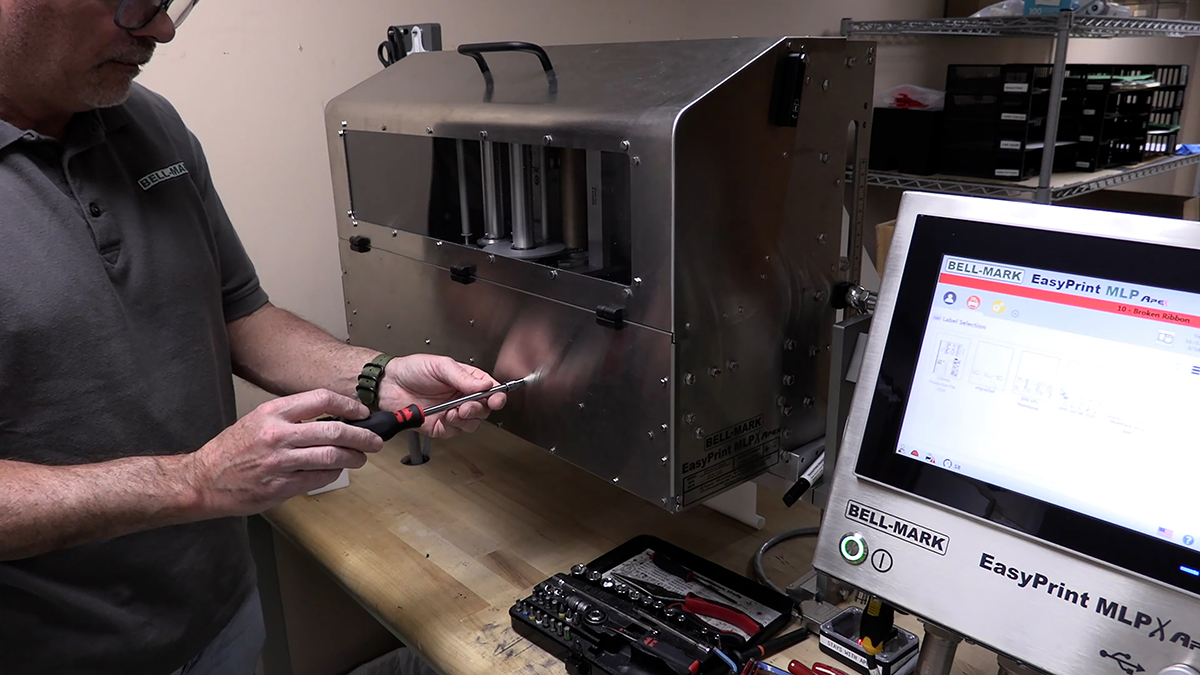

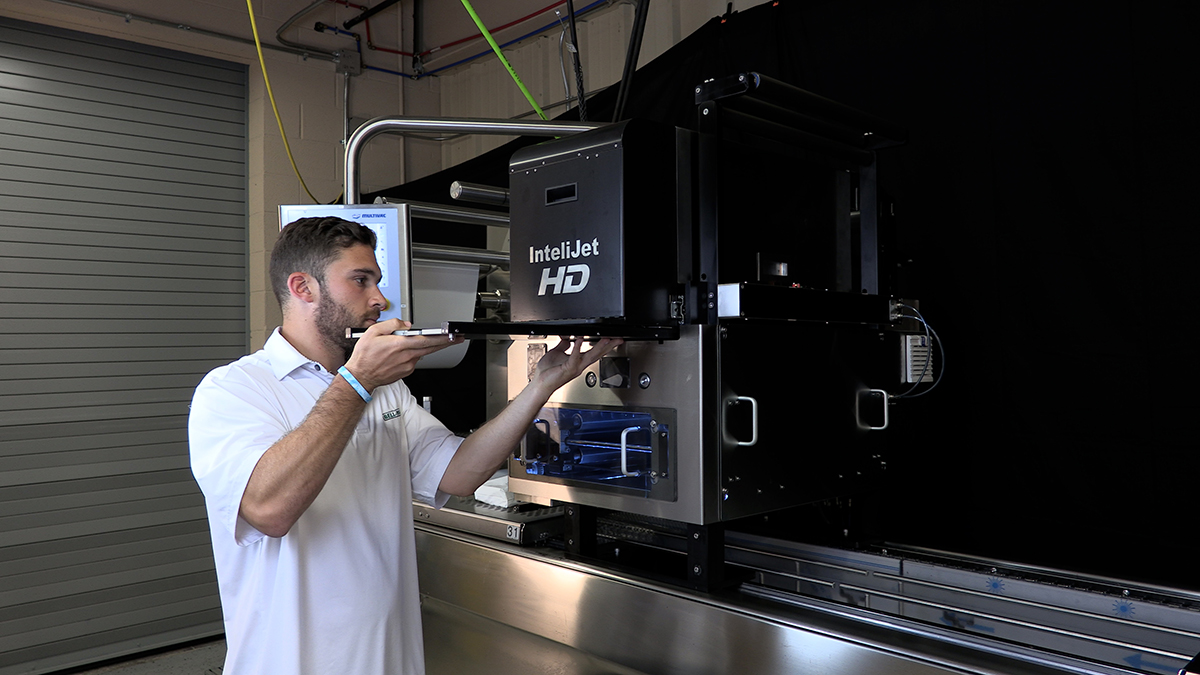

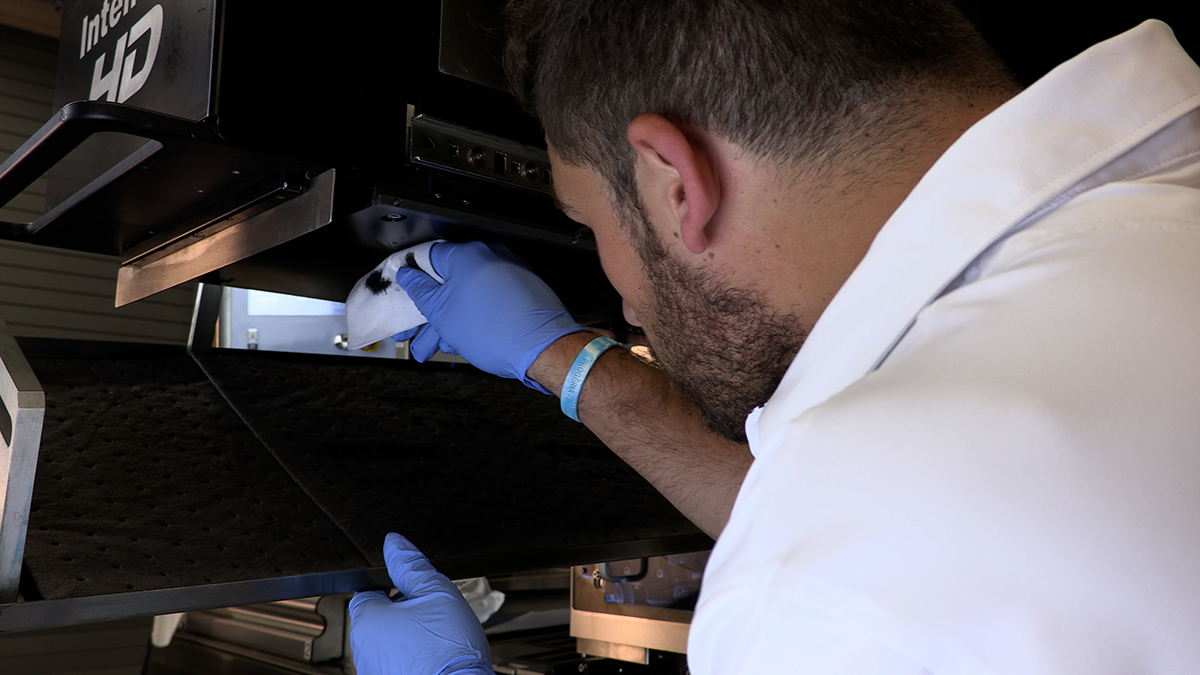

Field Service Technician

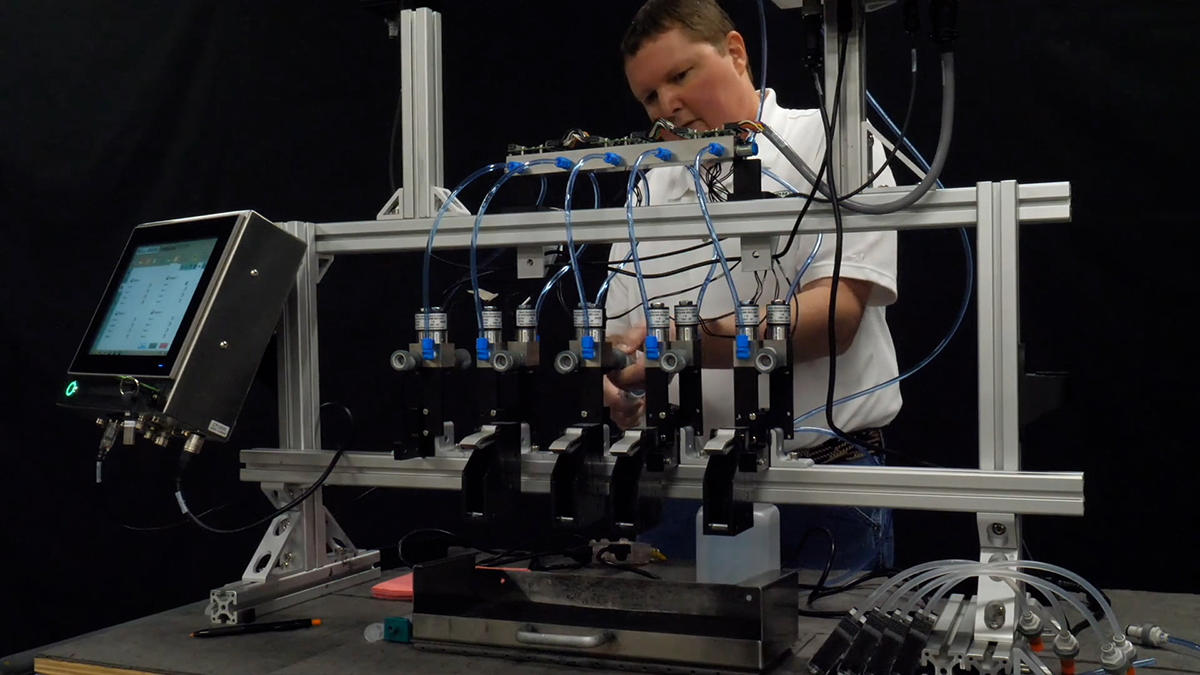

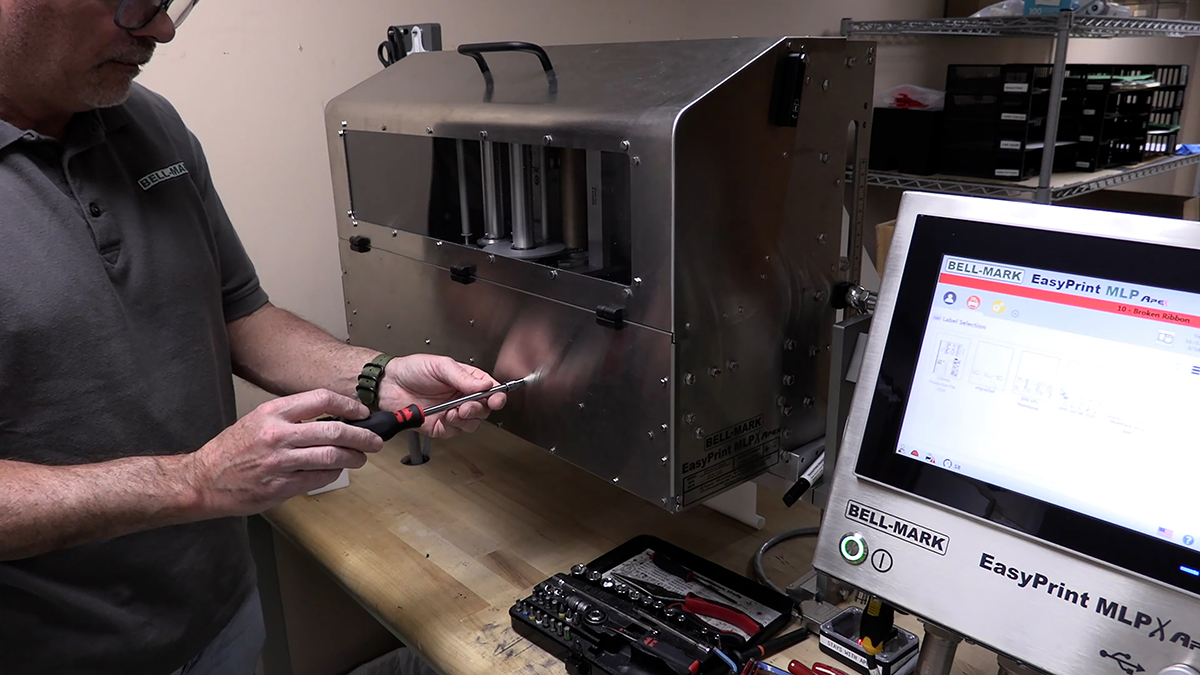

Bell-Mark Technologies is currently seeking to fill the position of a Field Service Technician. Successful candidates will be responsible for the installation, start-up, training, and troubleshooting of a wide range of electro-mechanical and electronic equipment. They work

closely with other internal departments, as well as providing customer phone assistance.

Roles and Responsibilities

- Performs inspection and troubleshooting and repair of Bell-Mark equipment at customer locations.

- Performs installation, acceptance testing and validation of equipment/production lines.

- Performs preventative maintenance inspections on equipment.

- Program equipment with various programmers and utilities.

- Resolve customers’ concerns efficiently and effectively.

- Provide technical training on new equipment to customer operators, maintenance, and engineering personnel.

- Advise customer of recommended service intervals.

- Communicates with the customer prior to and while onsite to determine the nature of the service/repair.

- Comply with all safety regulations and PPE requirements.

- Attend and participate in service training when available.

- Maintaining assigned tools and spare parts.

- Promptly and accurately complete all required documentation.

- Track time and materials for services rendered.

- Extensive travel, including overnight and international, is required.

- Maintain a professional appearance and demeanor while exhibiting a high level of customer satisfaction.

Qualifications and Education Requirements

- Associates degree, trade school or equivalent experience.

- Strong electronic and mechanical troubleshooting skills.

- In-depth knowledge of computers and computer operated equipment.

- Strong communication skills, both verbal and written.

- A self-starter who can work independently.

- Working knowledge of hand tools as well as basic power tools.

- Working knowledge of electronic troubleshooting tools.

- Ability to lift 50 pounds unassisted.

- Ability to stand on your feet for extended periods of time.

- Must have a valid driver’s license.

Preferred Skills

- Experience with packaging machinery is preferred.

Company Provided Benefits

- Company Provided Benefits.

- Company pays 95% of Health Insurance.

- Generous HSA payment.

- Tools provided.

- Company provided attire

- On-call pay.

- Company credit card, employee keeps frequent flyer awards.

- All travel expenses paid including daily Per Diem.

- Company provided safety gear.

Job Details

- Job type: Full-time

- Salary: $55,000.00 - $65,000.00 per year

Benefits

- 401(k).

- Employee assistant program.

- Health insurance.

- Health savings account.

- Life insurance.

- Paid time off.

- Referral program.

Schedule

Education

License/Certification

- Driver's License (Required)

Willingness to travel

Office Manager

Bell-Mark Technologies is seeking a new Office Manager. The Office Manager is responsible for the overall function and organization of the front office. As the Office Manager, you will act as the liaison between the manufacturing office and sales office with payroll,

accounts payable, and on-boarding enrollments of new and/or existing employees. The Office Manager will work with multiple department heads and other employees to ensure the overall progress of the company.

Roles and Responsibilities

- Entry of payroll timecards and detailed book-keeping of employee vacation and time off.

- Oversee the initial process of accounts payable; assist in the 4-way matching process, entering invoices into ERP systems, effectively communicate w/ the accounting department, work w/ vendors and/or purchasing to correct any discrepancies.

- Maintain Quicken checking account and petty cash box.

- Coordinate w/ department managers w/ new hire and on-boarding paperwork.

- Maintain and update electronic employee records and personnel files.

- Prepare, enroll, and act as the liaison for insurance and 401K paperwork for employees and the sales office.

- Work alongside the Purchasing Manager to keep office supplies appropriately stocked.

- Assist the operations manager w/ sales order processing and releasing of parts (training provided).

- Assist General Manager in daily office tasks and requests.

- Keep multiple company calendars up to date w/ scheduling meetings and interviews accordingly. As well as participate in meetings and record notes accordingly.

- Overall office functions such as answering multiple phone lines, copy/scan documents, and maintain a clean and organized workspace.

Qualifications and Education Requirements

- Kind and outgoing personality as you are the first person visitors and employees greet.

- Excellent organization/time management skills

- Strong computer skills (Microsoft Office: Outlook, Word, etc.).

- Strong communication skills, both written and verbal.

- Ability to prioritize and assist in the daily workload and function of the company.

- Ability to work independently.

- Ability to learn and adapt to new tasks and work well with others.

CNC Programmer

We are seeking a skilled and experienced CNC Programmer to join our manufacturing team. This individual will be responsible for the programming, setup, and operation of computer numerical control (CNC) machines to produce high-quality precision parts. This role requires an

understanding of blueprints, engineering drawings, and technical specifications to ensure products are created accurately and on schedule.

Roles and Responsibilities

- Develop and write CNC programs using CAD/CAM software for various CNC machines, including mills and lathes.

- Analyze engineering drawings, 3D models, and technical specifications to determine optimal machining strategies

- Optimize tool paths and machine set-ups for maximum efficiency and precision.

- Determine appropriate cutting tools, spindle speeds, feed rates, and other machine parameters based on material properties and machining requirements.

- Perform quality inspections of finished parts using measuring instruments such as calipers, micrometers, and gauges.

- Work closely with machinists to troubleshoot any problems during the manufacturing process, identify areas of improvement, and implement effective solutions.

- Perform regular program revisions and updates as needed to accommodate design changes or improve machining processes.

- Assist in the development of standard operating procedures (SOPs) for CNC programming.

- Provide training and guidance as needed.

Qualifications and Education Requirements

- High school diploma or equivalent; associate's degree or trade certification in a related field is preferred.

- Proven experience as a CNC programmer, ideally with 3+ years in a manufacturing environment.

- In-depth knowledge of 3D CAD/CAM programs such as SolidWorks and SolidCAM; G-Code programming experience is a must.

- Demonstrated ability to interpret blueprints, engineering drawings and technical specifications accurately.

- Strong troubleshooting skills and the ability to quickly identify issues with machinery or processes.

- Excellent attention to detail and a commitment to producing high-quality work.

- Strong communication skills with both technical and non-technical team members.

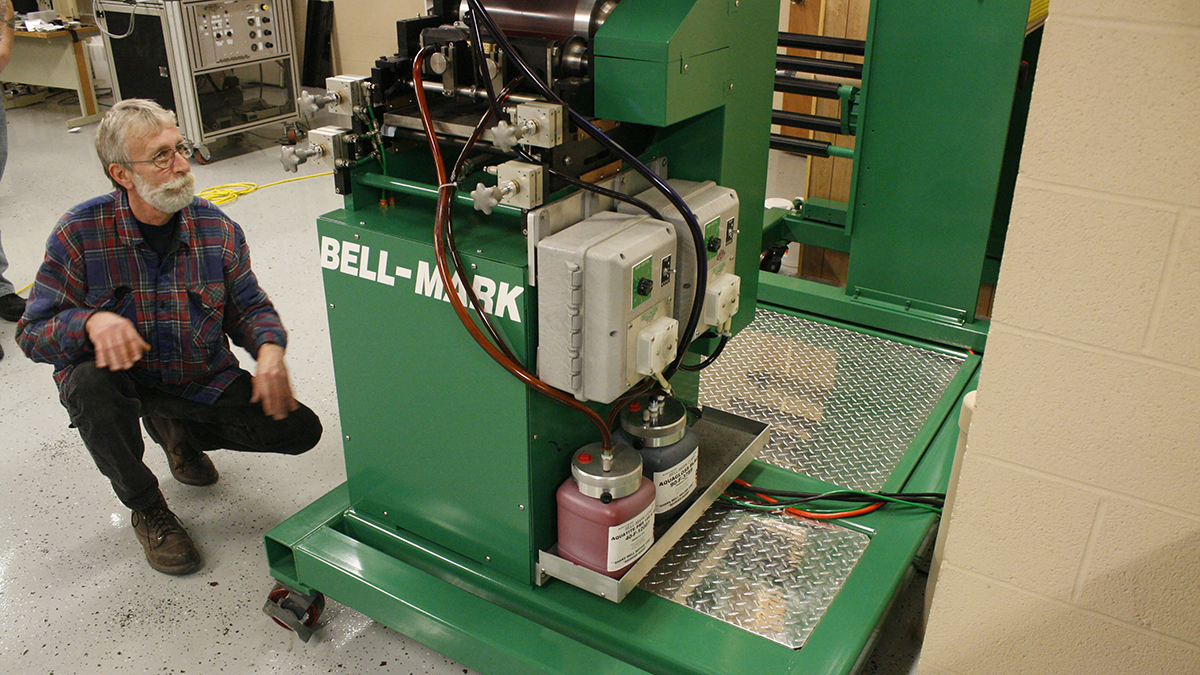

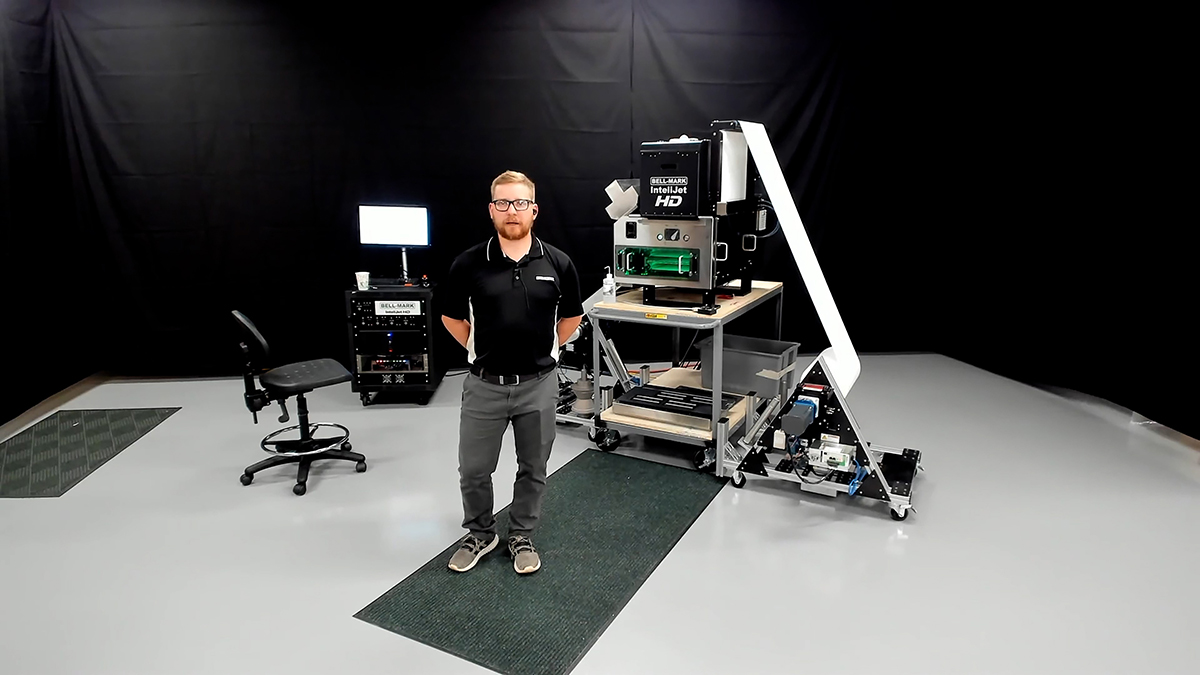

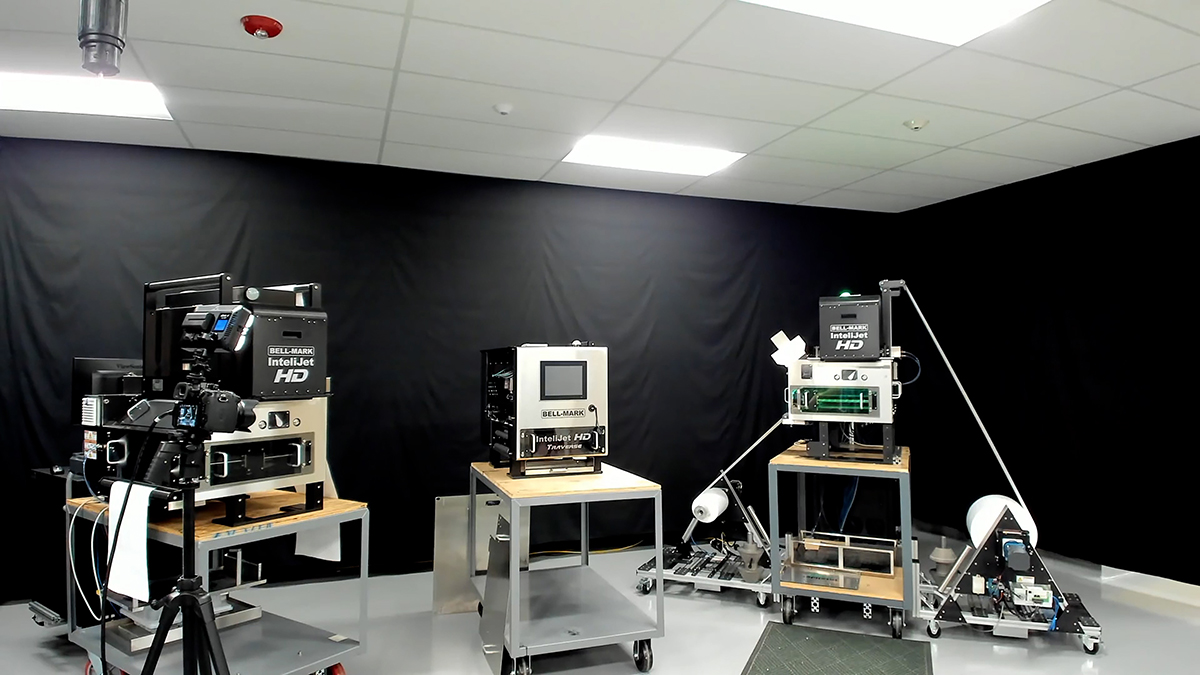

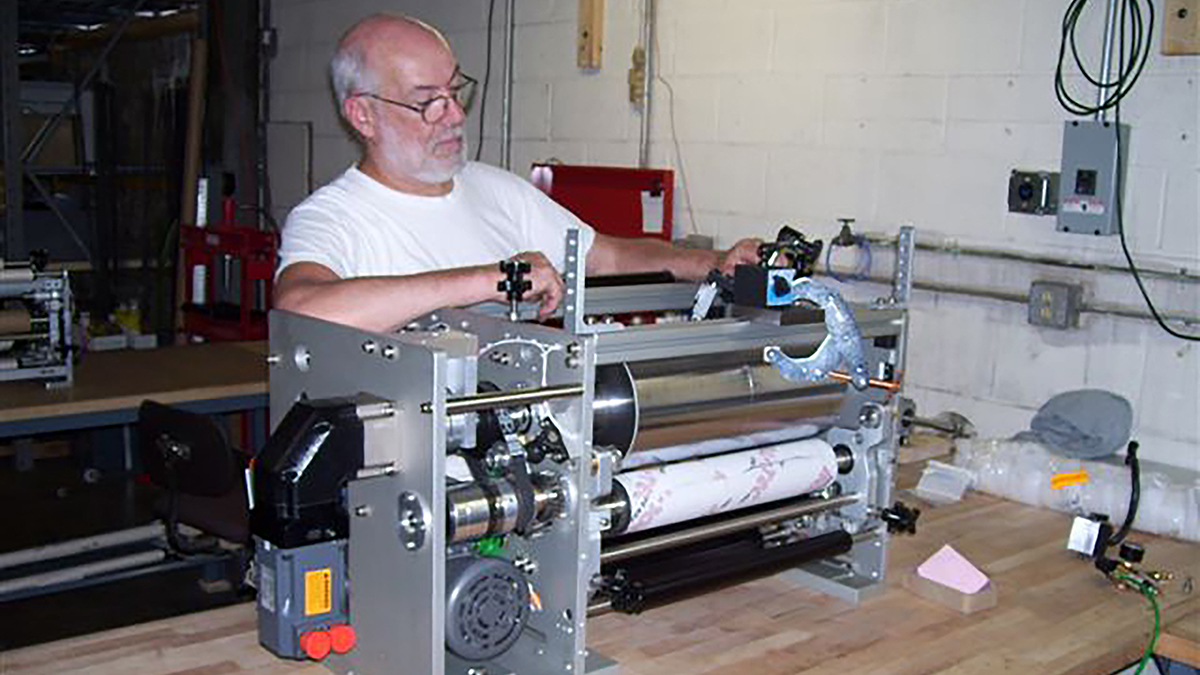

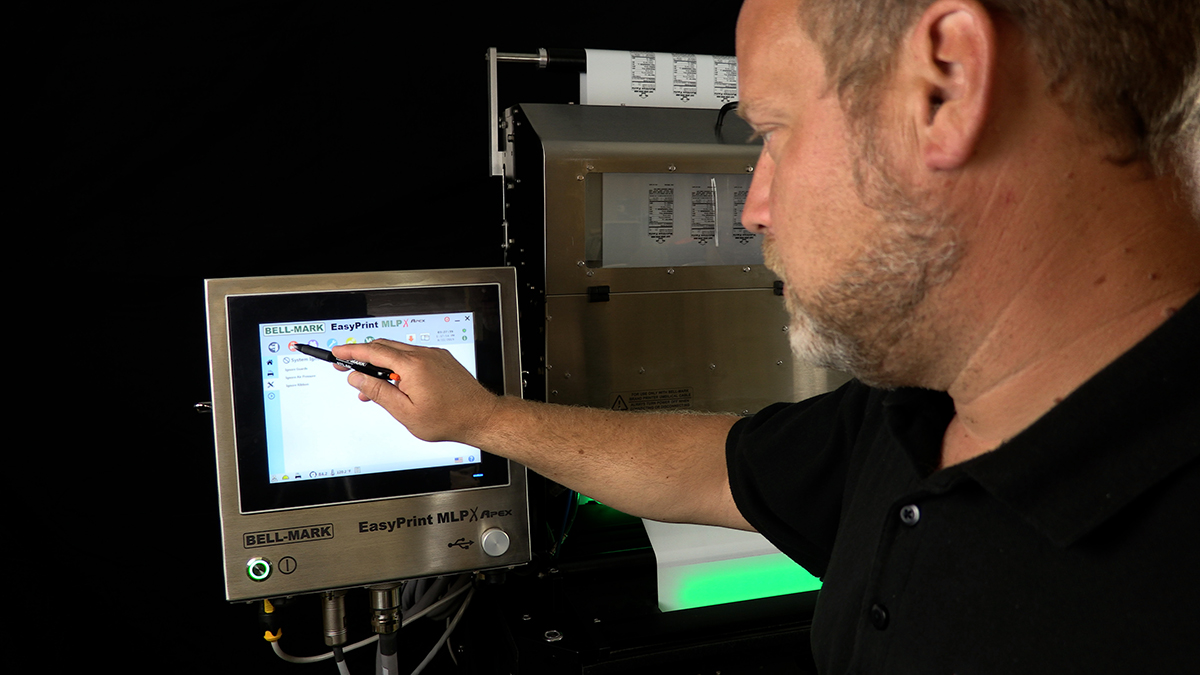

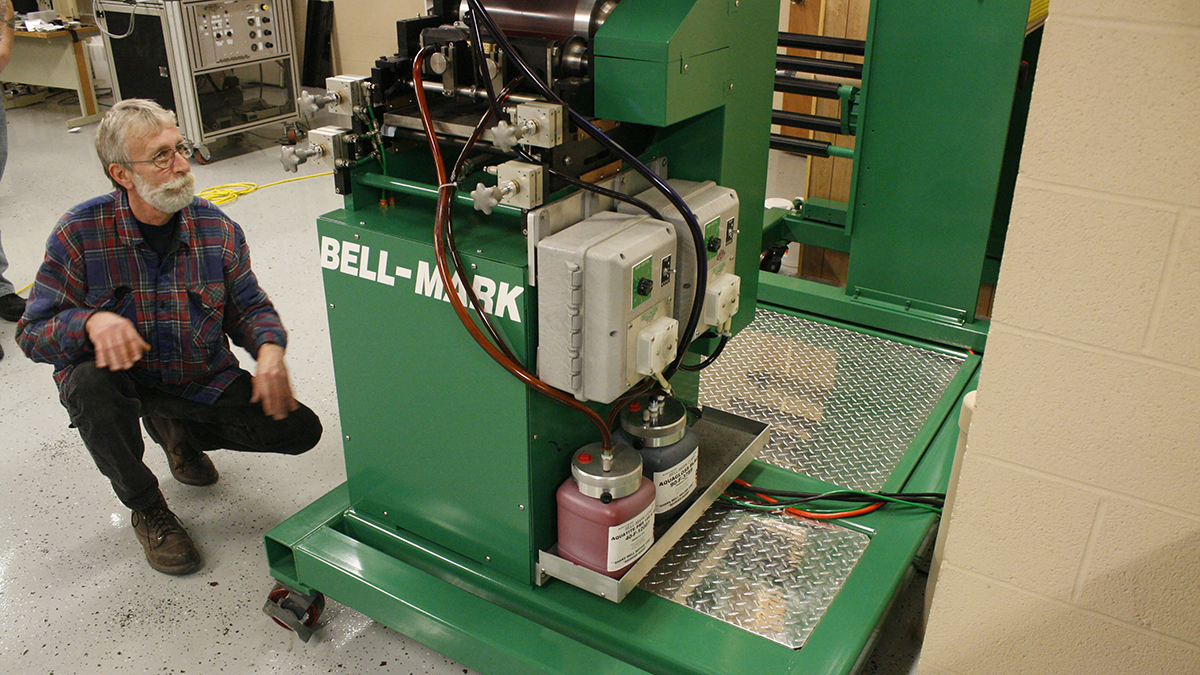

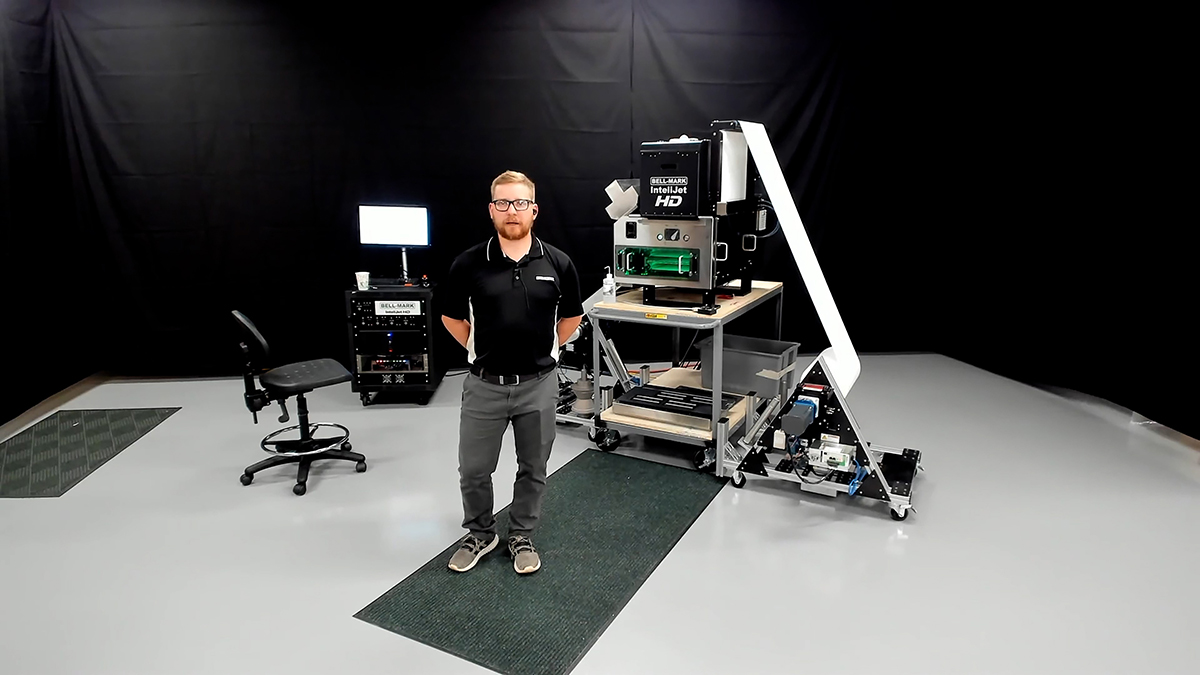

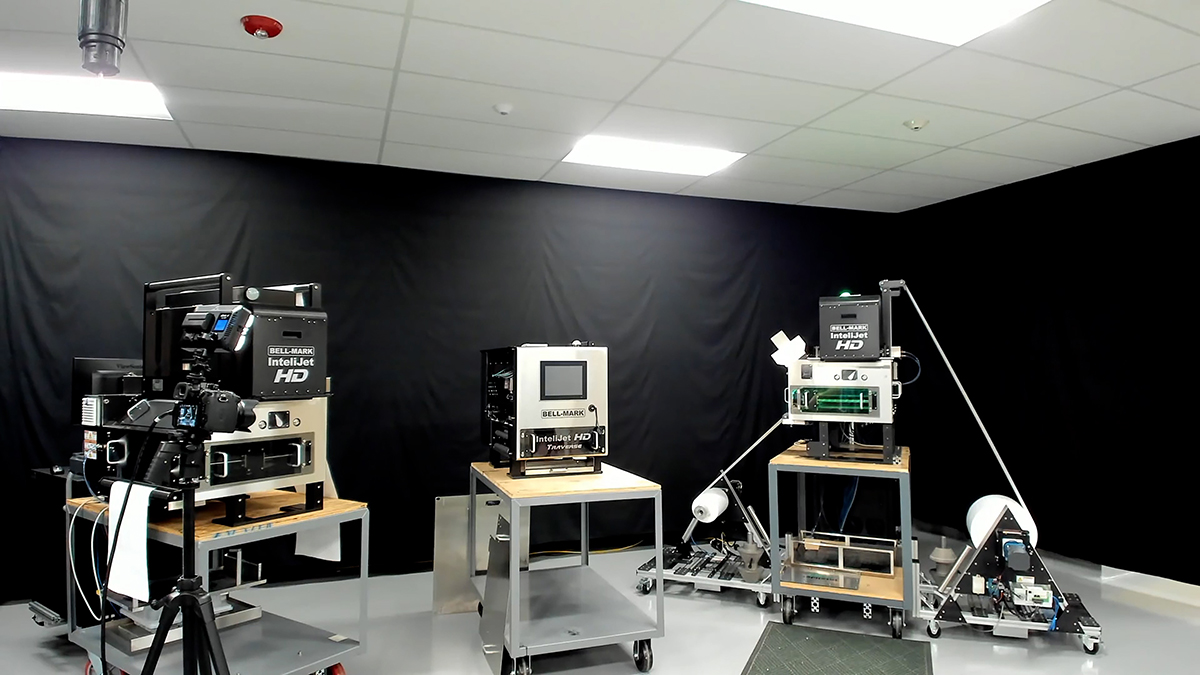

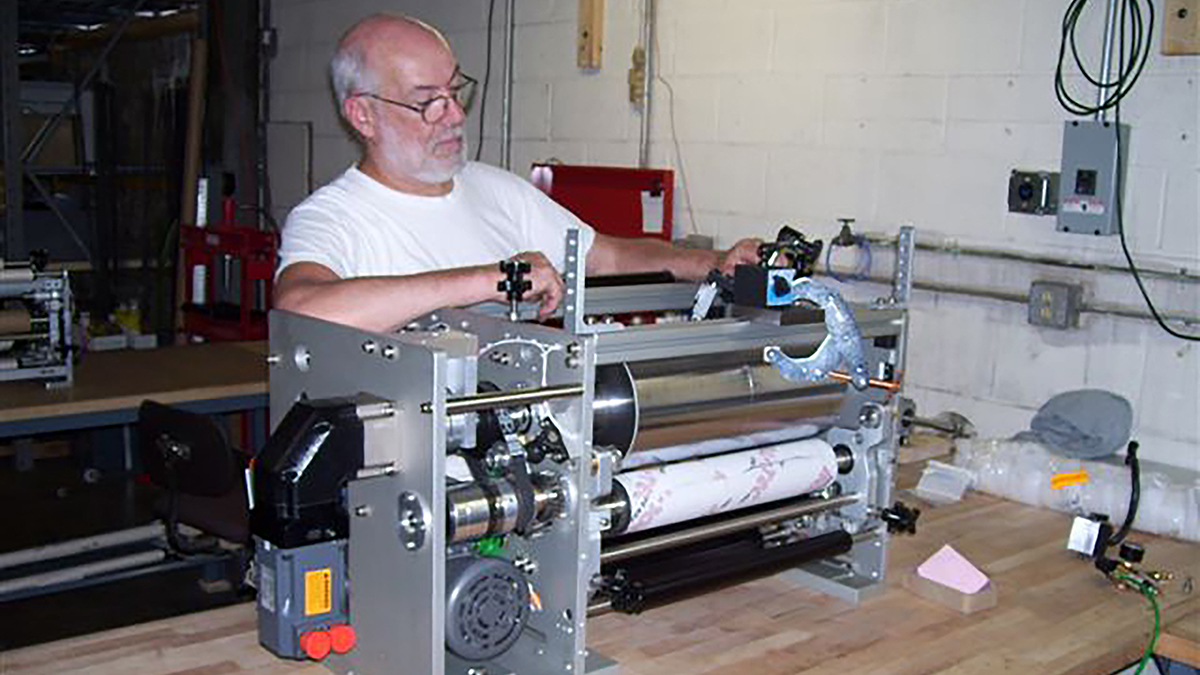

For over 60 years, BELL-MARK has been developing innovative solutions for package and carton printing applications in the medical device, pharmaceutical, prepared foods, meat, bakery, dairy, and poultry packaging industries. BELL-MARK offers many in-line printing technologies

including piezo inkjet, thermal inkjet, thermal transfer, flexographic, and ink coder, all of which satisfy requirements to print directly onto package and carton substrates.