The Future of On Demand Printing

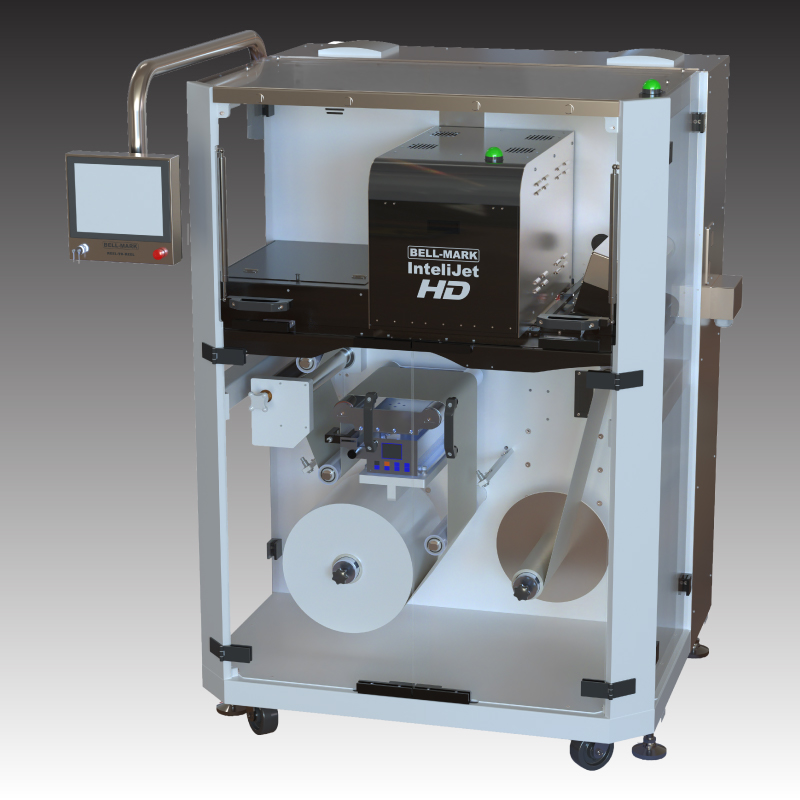

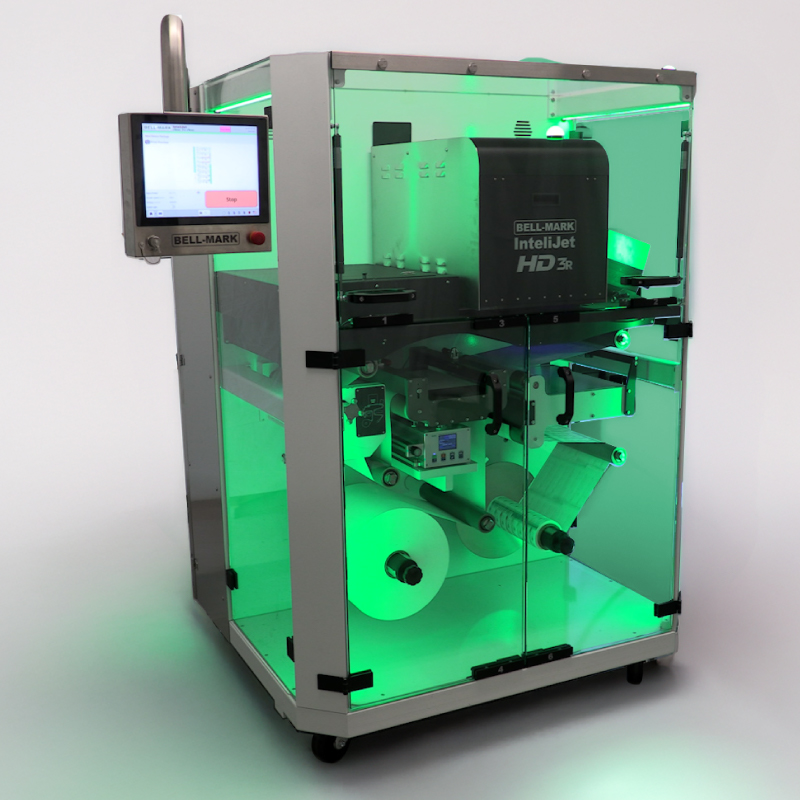

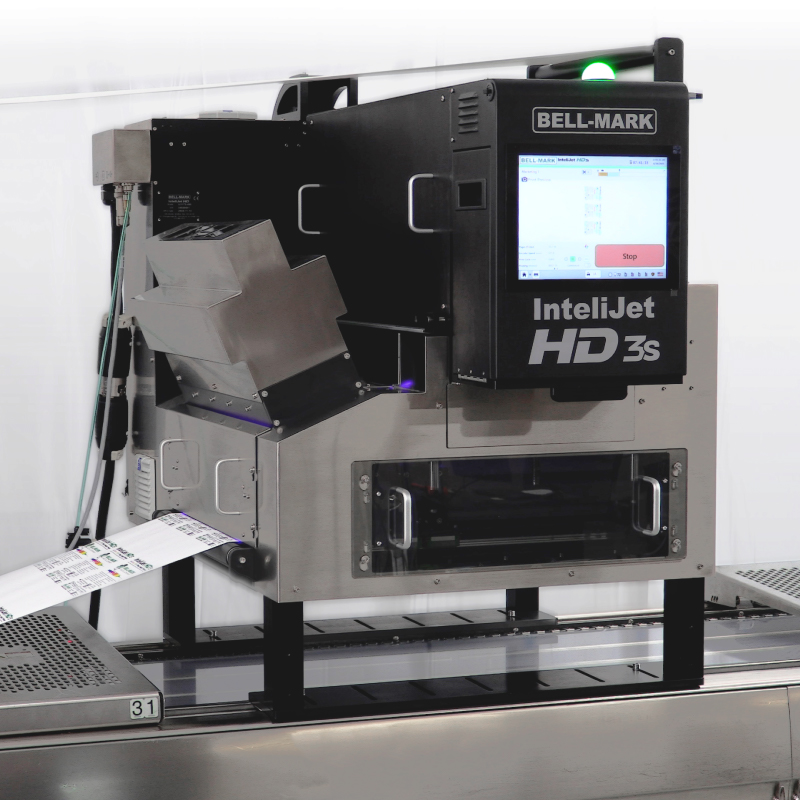

Introducing the InteliJet HD 3—the newest generation of BELL-MARK's high-definition piezo inkjet printers. Engineered for the most demanding packaging environments, the HD 3 combines industry-leading, high-performance print heads with 600 DPI print quality, next-level automation, maximum reliability, and ultra-fast print speeds. HD 3 is more than just a printer; it's a smart investment that will future-proof your production line for years to come.

- Lowest cost of ownership compared to other printing systems.

- Little to ZERO maintenance.

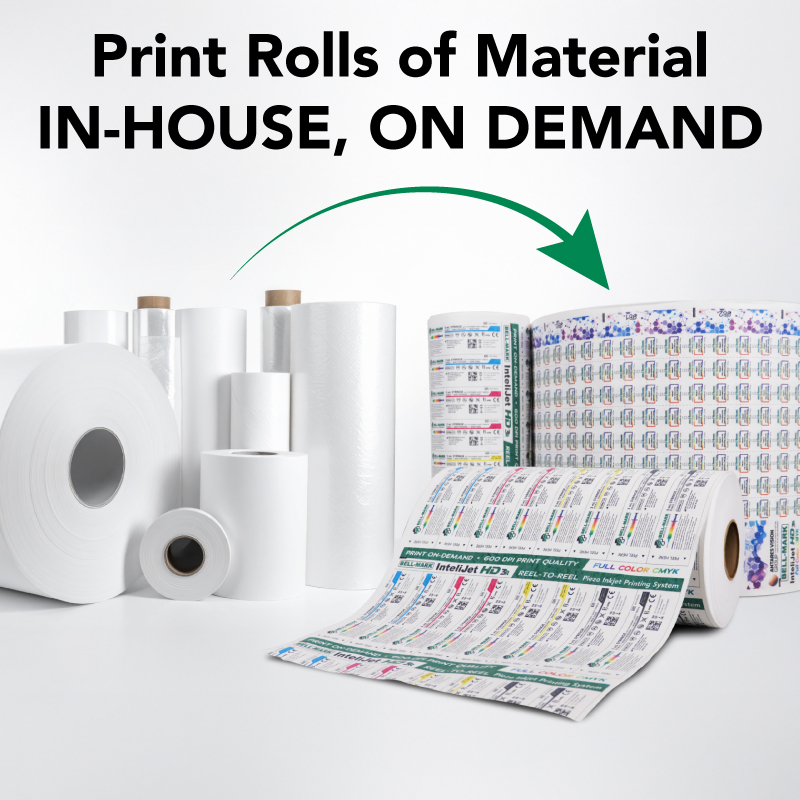

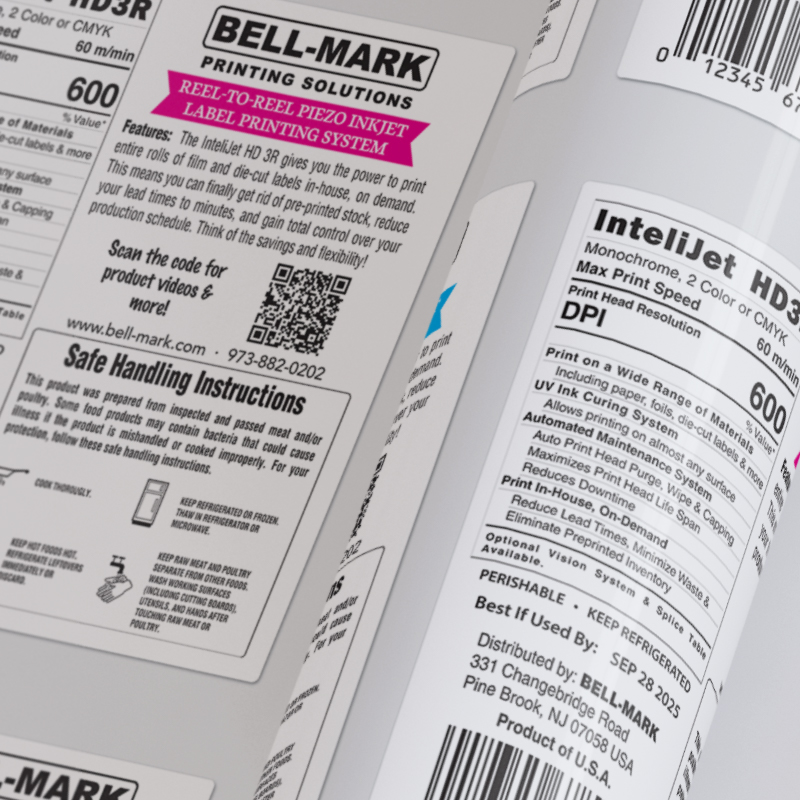

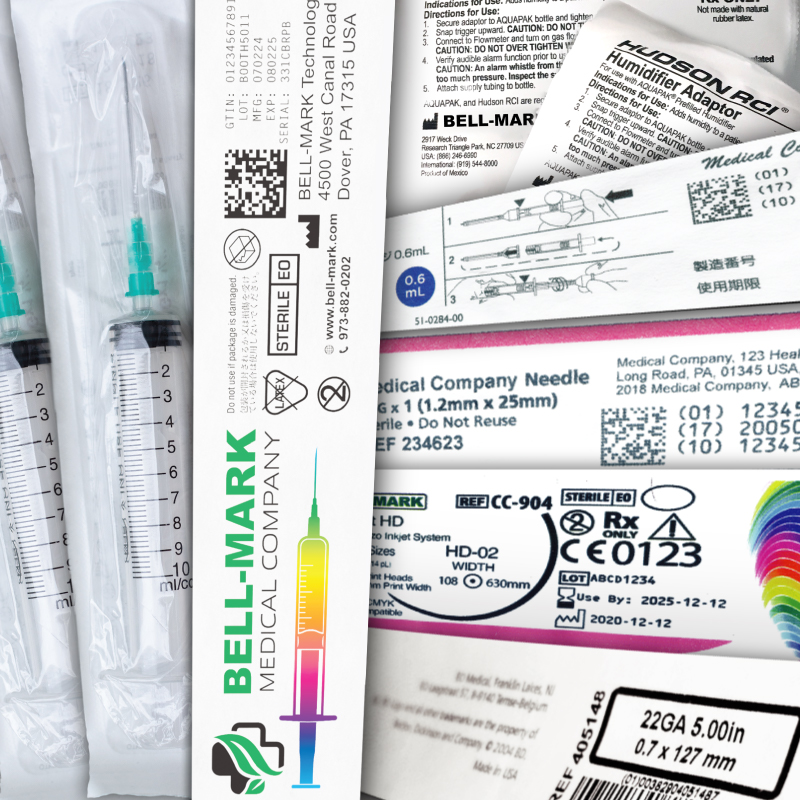

Print entire packages on-demand including all variable data, directly on to almost any surface with UV-cured or water-based inks. The InteliJet HD 3 is available in 3 unique models, each custom-designed for specific applications to deliver maximum performance:

- 1a - Accumulator System

- 4r - Reel-To-Reel System

- 5s - Servo Web Advance System

Features

- LED UV Curing System. Instantly cures and protects the ink to guarantee lasting print quality.

- Built-in Automatic Print Head Purge, Wipe, & Capping. Reduce downtime with automatic maintenance at the push of a button, ensuring maximum print head life and the highest print quality at all times.

- Network Connectivity. Connect to an ERP system and utilize Hot Folder to use existing label software like Prisym, Labelview, Bartender, and more. Network connections include Ethernet, TCP/IP, OPC-UA (can be client or server), Serial (RS232), Hot Folder, and more.

- Splice Detection. Retracts and protects the print heads from web splices without stopping production.

- Advanced User Interface. Built-in 307mm touchscreen for controlling all aspects of the printer.

- BELL-MARK Layout / Label Creation tools provide the ability to design and modify print templates using an extensive array of editing tools.

- Integrated help system that provides a convenient way to view tutorial videos step-by-step instructions on how to perform maintenance tasks.

- Create customized workflows for an enhanced customer experience.

- Supports all types of variable information (text, barcodes, date codes, serialization) and over 80 types of barcodes including: GDS1-128, GS1-Datamatrix (2D), EAN 13, EAN 14, Code 39, Code 128, UPC A, SSCC18, PZN, and QR-Code.

- Remote Support. The InteliJet HD has remote training and support, only requiring an internet connection.